VMC Milling ( 5 Axis )

VMC Job Work

Table Size : - 1300 mm x 610 mm x 610 mm

Rotary Size : - 300 mm x 800 mm

Component Type : - Die Mold, Punch, Fixture

Material Grade : - Steel, Stainless Steel, Non Ferrous , Super Alloy

Material Hardness : - Up to 65 HRC

We at Cretek Engineering Pvt Ltd having a table size 1300 mm x 610 mm x 610 mm 5 axis VMC Milling Machine to provide milling job work. We have ability to do milling process with rotary option also. We have developed for milling with material like super alloy, Steel, Stainless Steel, Non Ferrous. Machine processes done with different material types like Steel, Stainless steel, Non Ferrous, Super alloy etc. We have VMC milling machine located in kubadthal, Gujarat doing milling process for material hardness up to 65 HRC.

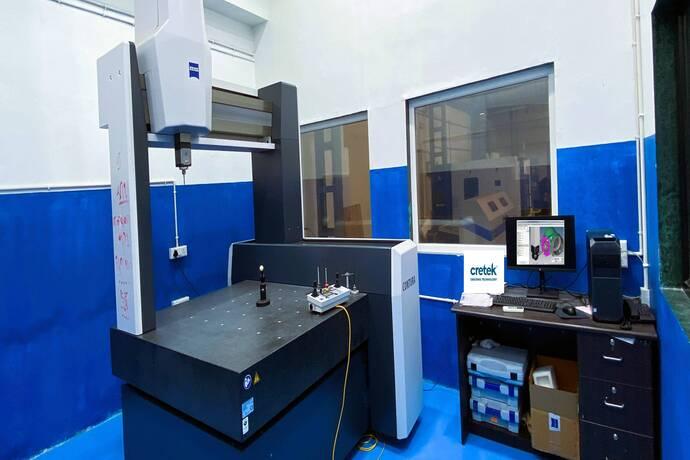

We are equipped with high-quality milling tools to produce custom machined parts with our 5-axis milling machines, we offer VMC milling parts job work services for different industries. Cretek Engineering Pvt. Ltd. has a well-equipped quality assurance department and a quality management system with all required QC instruments. Our QC and QA teams monitor all machining processed components to ensure that customer requirements meet accurate quality specifications.

With VMC milling services, any parts which required both turning and milling processes can be produced within a few hours. once you contact us, we will submit you a quote within 24 hours and complete the project within your project timeline.

The surface finish of machining parts are important to consider. This is because it can affect the function of the part and aesthetics point of view. We worked with following surface roughness standards The typically machined surface roughness is RA 3.2-1.6 μm, The smooth machined surface roughness is Ra 1.6-0.8 μm, The super-finished surface roughness is Ra 0.8-0.2 μm.

We manufacturing all components with considers of ISO 2768 Industrial standards for all machining components. so that our products meet the highest quality standards. Typically, we can hold a VMC milling tolerance from ± 0.125mm to ± 0.05mm or even tight tolerance of ± 0.01mm.

We offer other services also like Deep Hole Drilling, Gundrilling, Honning, CNC Turning, CNC Turn-milling, CMM Inspection, Etc....