BTA Deep Hole Drilling

Deep Hole Drilling Job Work

Drilling Size : - 40 mm to 320 mm

Drilling Length : - Up to 8000 mm ( Single Side 8000 mm )

Job Clamping Dia. : - Up to 1000 mm.

Component Type : - Square Bar, Round Bar, Step Bar

Material Grade : - Steel, Stainless Steel, Non Ferrous , Super Alloy

Material Hardness : - Up to 65 HRC

CNC BTA deep hole drilling machine, Imported for drilling solutions with capacity ID up to 320mm, length up to 8000 mm ( Single Side 8000 mm) and clamping Dia. up to 1000mm with any kind of shape like square Bar, Round Bar, Step Bar etc. Our machine and Specialized tooling is capable to do drilling operation in various metals like Steel, Stainless Steel, Non Ferrous metal, Super Alloy metal with Hardness of Up to 65 HRC.

We are specialized in services of BTA Deep hole drilling solutions, where we provide deep hole drilling operations/Job work. We have achieved many milestones while providing Deep hole drilling process to our reputed clients located in Kubadthal, Bakrol, Kathwada, Odhav, Vatva, Naroda, Chhatral, Etc in Ahmedabad, Also provide Job work to the customers in Baroda, Vallabh Vidhyanagar, Surat, Anand Etc. in Gujarat and also We are providing services in Pan India.

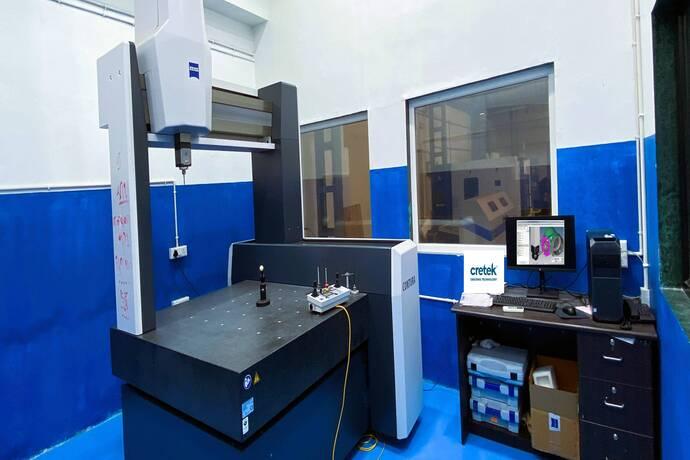

Our methodology, strict compliance to QC/QA standards differentiates Cretek Engineering Pvt. Ltd. from competition. In the last few years we have paid lots of our time to optimize processes for single hole barrels and twin hole barrels in terms of accuracy, workmanship & performance. This activity has resulted in tremendous improvement in most important matrix like hole straightness, Bore tolerance and surface finish. We are a one stop job shop for all Deep Hole Drilling solution.

Our services in Deep hole drilling machine job work give fast delivery as we use special world class tooling and specific setups to deliver high quality jobs. BTA deep hole drilling process in Cretek Engineering Pvt Ltd handled by expert technicians who are well worse with application and perform drilling Operations successfully. This allows manufacturers to achieve their manufacturing tolerances and production requirements reliably, accurately, and efficiently. BTA Deep Hole drilling process is the most effective method of drilling deep hole, as it is a cleaner, more reliable and capable process than conventional drills, and can achieve larger diameters and higher feed rates than the other options.

We offer other services also like Gundrilling, Honning, CNC Turning, CNC Turn-milling, VMC Milling, CMM Inspection, Etc....